Pt. Whitney Geoduck broodstock experiment

Setup

- Troubleshoot offline Apex

- reset router by little reset button, nothing happened

- SOULUTION: hard reset router by unplugging power supply

- apex light went from orange to blue to orange; and reconnected to fusion

-

- need to set Apex to notify when Fusion connection is lost

- create conditional: if connection lost:

- switch off outlet 2_8 (outlet 8 on the EB832 Tank1_low) for 10 seconds

- switch outlet 2_8 back on

- another potential solution

- Set up electricity

- Apex now plugged in to UPS battery backup

- UPS backup plugged into upper right-side GFI behind wall apex is on)

- Connected 2 pumps in tanks 3 and 4

- surge protectors are mounted on wall above tank 1 and tank 3

- pumps in tank 1 and 2 are plugged into surge protector above tank 1

- pumps in tanks 3 and 4 are plugged into surge protector above tank 3

- surge protectors are plugged into extention cord that runs above tanks and silos and is plugged into outlet 6 in Apex 1 power block (outlet “EB_5”, 2_6)

- Recalibrated pH probe 3 with pH standards and placed it back in tank 3.

- Now it’s reading too low. Maybe replace this probe?

-

Reduced gas flow in tanks 1 and 2 by slightly dialing back black knobs

- Feeding is happening in all tanks twice/day.

- food has a high pH

- Matt could fix this

- Variability in inflow water temp can be improved. The head tank is on a recirculating chiller right now and incoming water may be fluctuating more because of this. An HVAC guy is coming to fix this.

Remaining setup

- Apex data download; still need to figure this out for remote access

- Rig probe holders (to ensure probes go back in correct tanks and not under the crates)

- Install hooks to hang pumps on when tanks are being cleaned?

- decide on treatment pH values. Should the ambient treatment have pH control (set at 8) to reduce variation?

- method for turning off CO2 during tank cleaning

- 10-30-2018 gas gauge

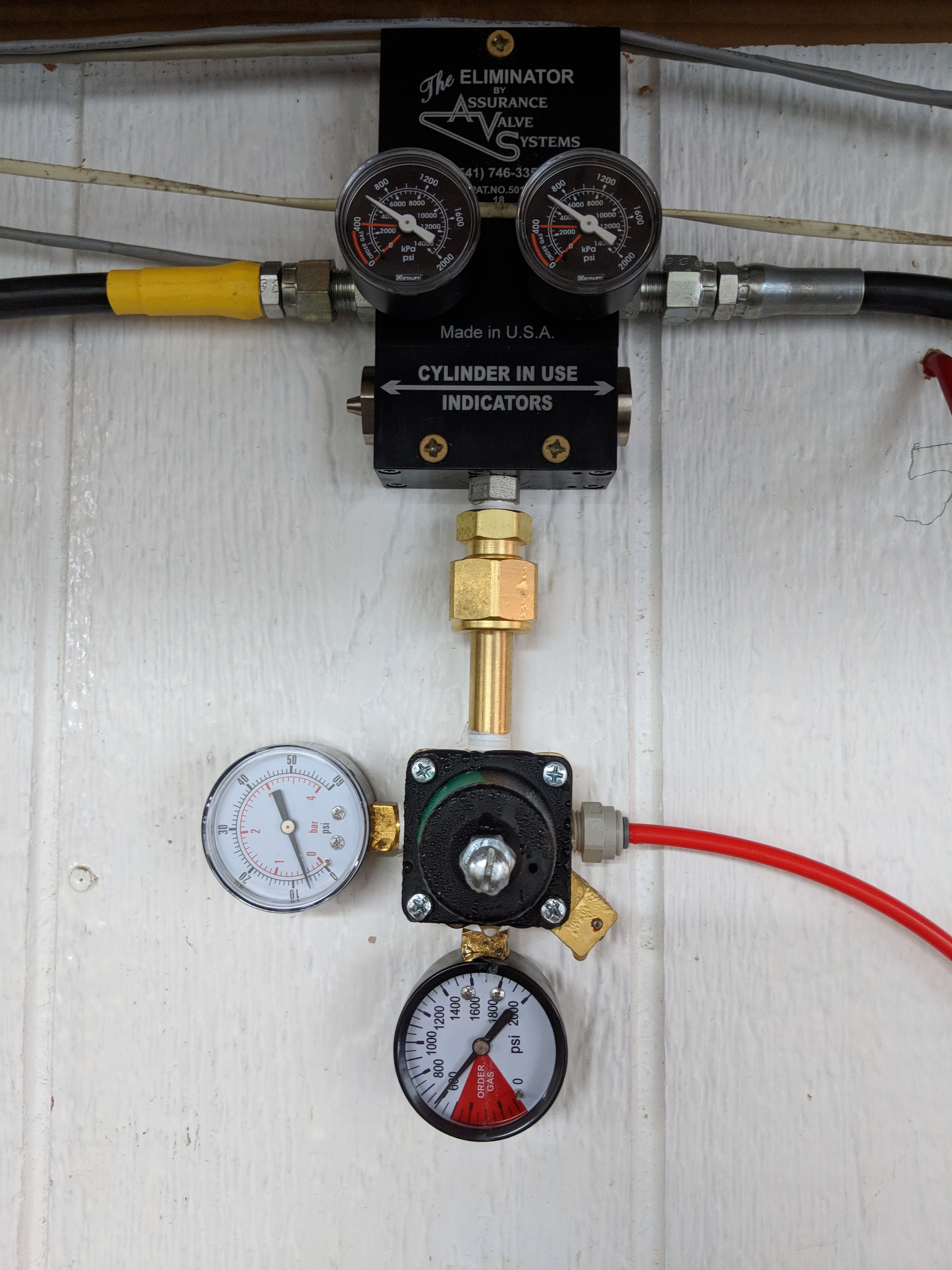

- 11-02-2018 gas gauge

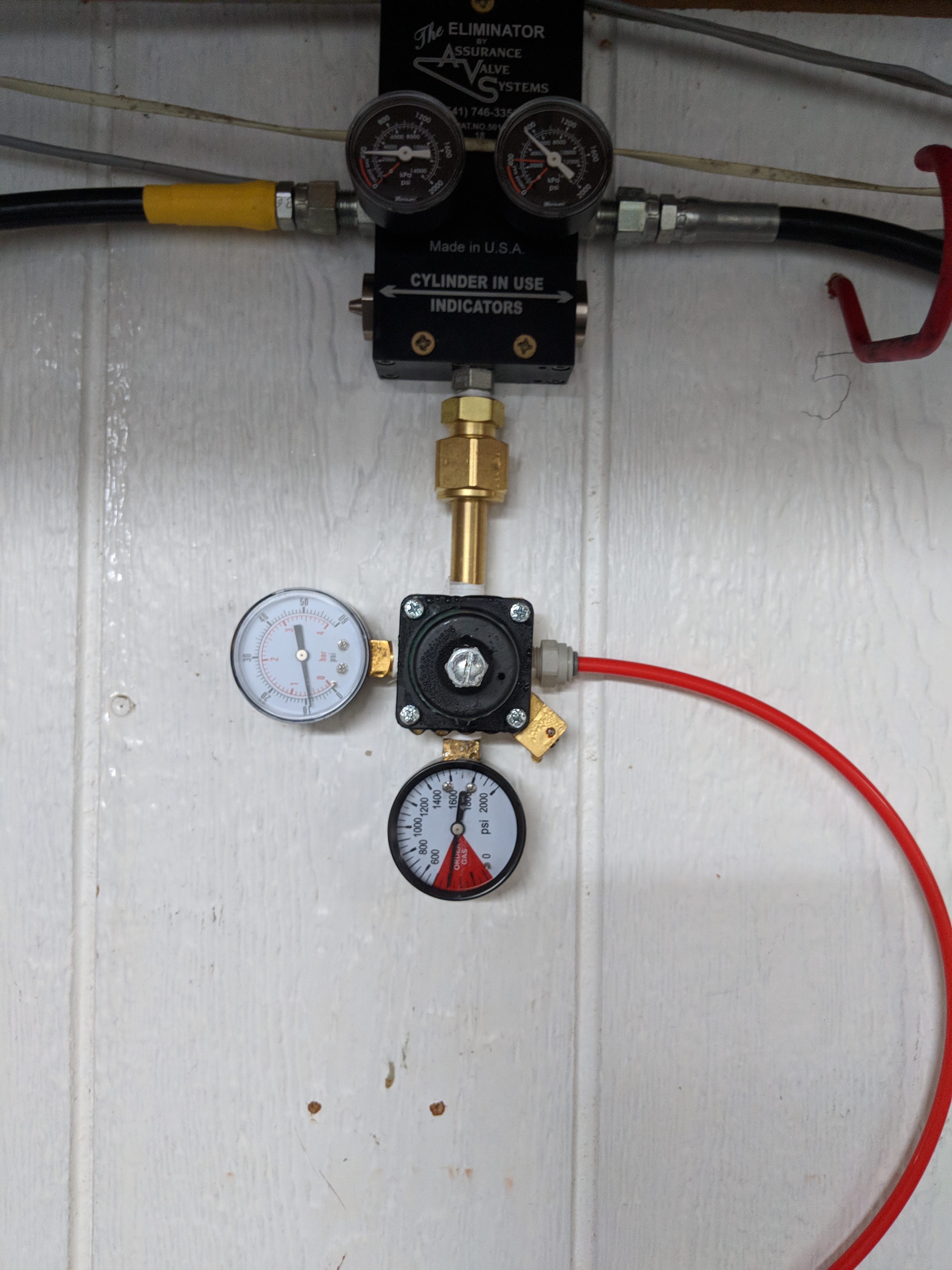

- 10-30-2018 gas gauge

- number clams (didn’t get to this but have nail polish)

- Get square milk crates?

- connectors between venturi injector and gas lines are too large for tubing; exchange for smaller ones?

Water sampling

- following Sam’s protocol

- video of titrator initial setup

- ran titrator pH calibration 2x to get correct, 2nd time I used fresh pH 7.0 buffer

- ran CRMs with ‘CRM’ program, should have been ‘007’ program (not mentioned in titrator protocol)

- reran CRMs with ‘007’ program

- junk = 59.774g

- CRM1 = 59.9790g

- CRM2= 59.6699g

- CRM data

-

calibrating Orion (Thermo) pH probe: 1) click mode to get to pH mode 2) click cal 3) follow instructions (need DI water for rinsing)

- reading tris buffer: T27

- T = 20.04

- pH = 8.23

- salinity = 33.68, 33.59 PSU/51.58mS/cm/25.28ppt (DI water = 0.073psu, 20.19ppm)

- did not do calibration with tris samples at different temps. need to ask Sam about this protocol

- Sampling from tanks

- only sampled from tanks 1 and 2, because feedings were happening in 3 and 4 at the time

- filled up measuring cup

- got pH, temp, and salinity

- pH meter seems off after calibrating:

- pH didn’t match logger probes

- pH of standard pH 4.00 was reading at 3.0

- need Sam’s help with Tris calibration/methodology

- pH meter seems off after calibrating:

- pour into sample bottles

- wash/wipe probes between tanks

- filter from glass bottles into labeled titrator cups on scale (59-61g); didn’t do this, syringe filters (0.2um) are very hard to push water through

- ran samples on calibrated titrator