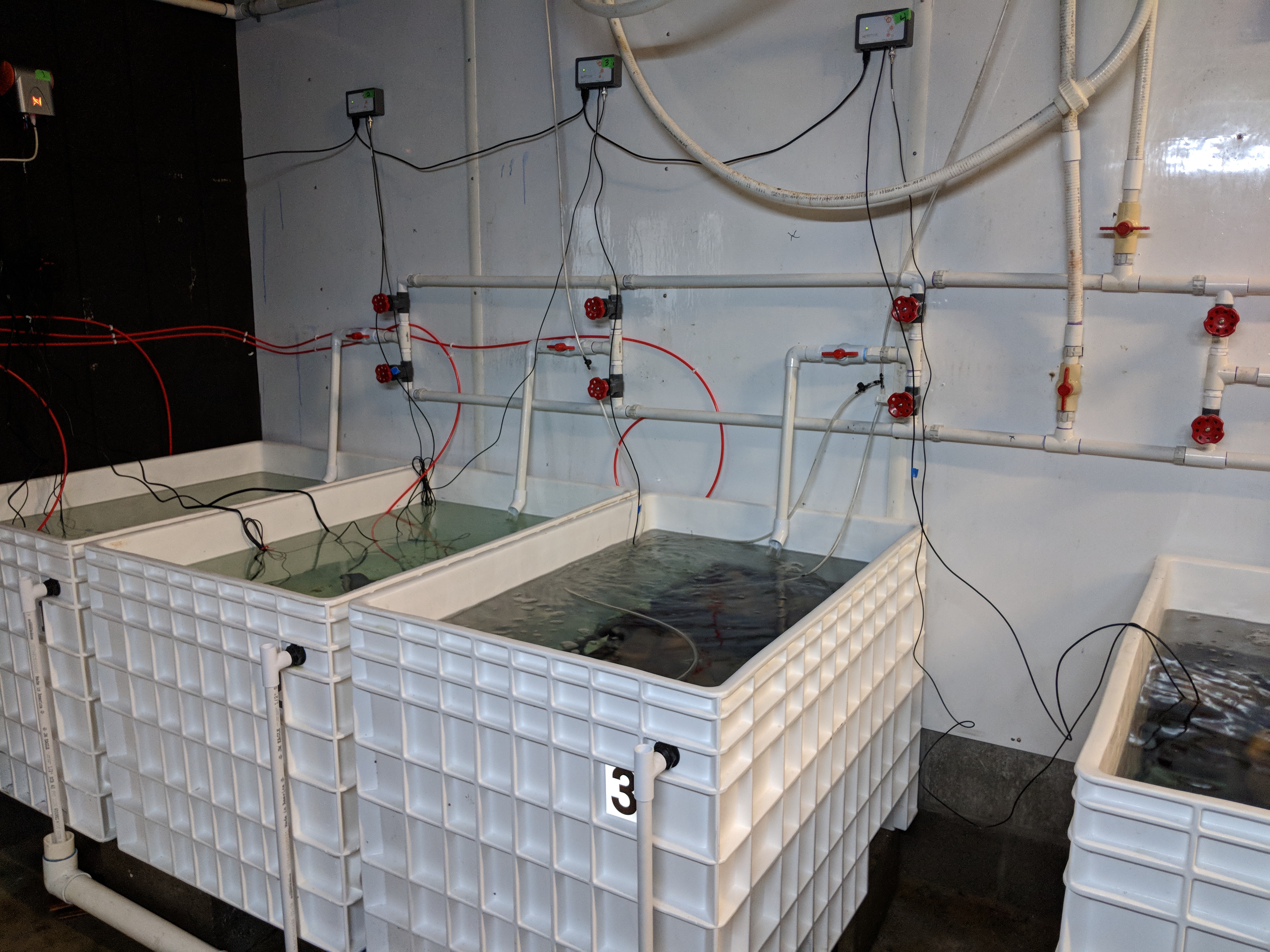

Broodstock experiment

need to:

- order KCl 3M 25mL pH probe storage solution, Mettler Toledo, # 51343180

- order CRMs (only 1 unopened bottle left)

- bring extension cord and power strip for adding pumps to tanks 3 and 4

- bring materials to label ducks (nail polish? superglue + labels?)

- something to fix probes in tanks?

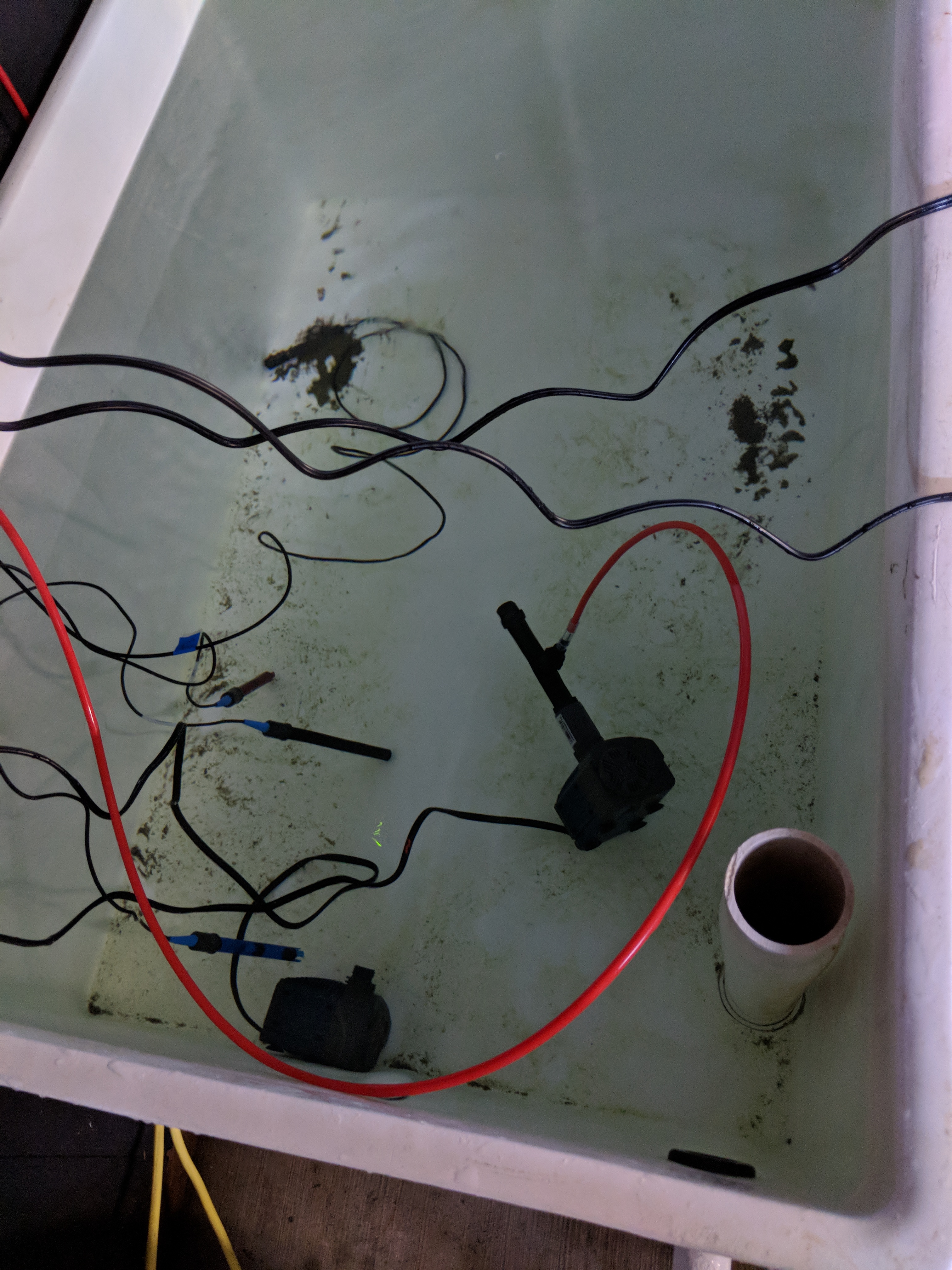

setup status

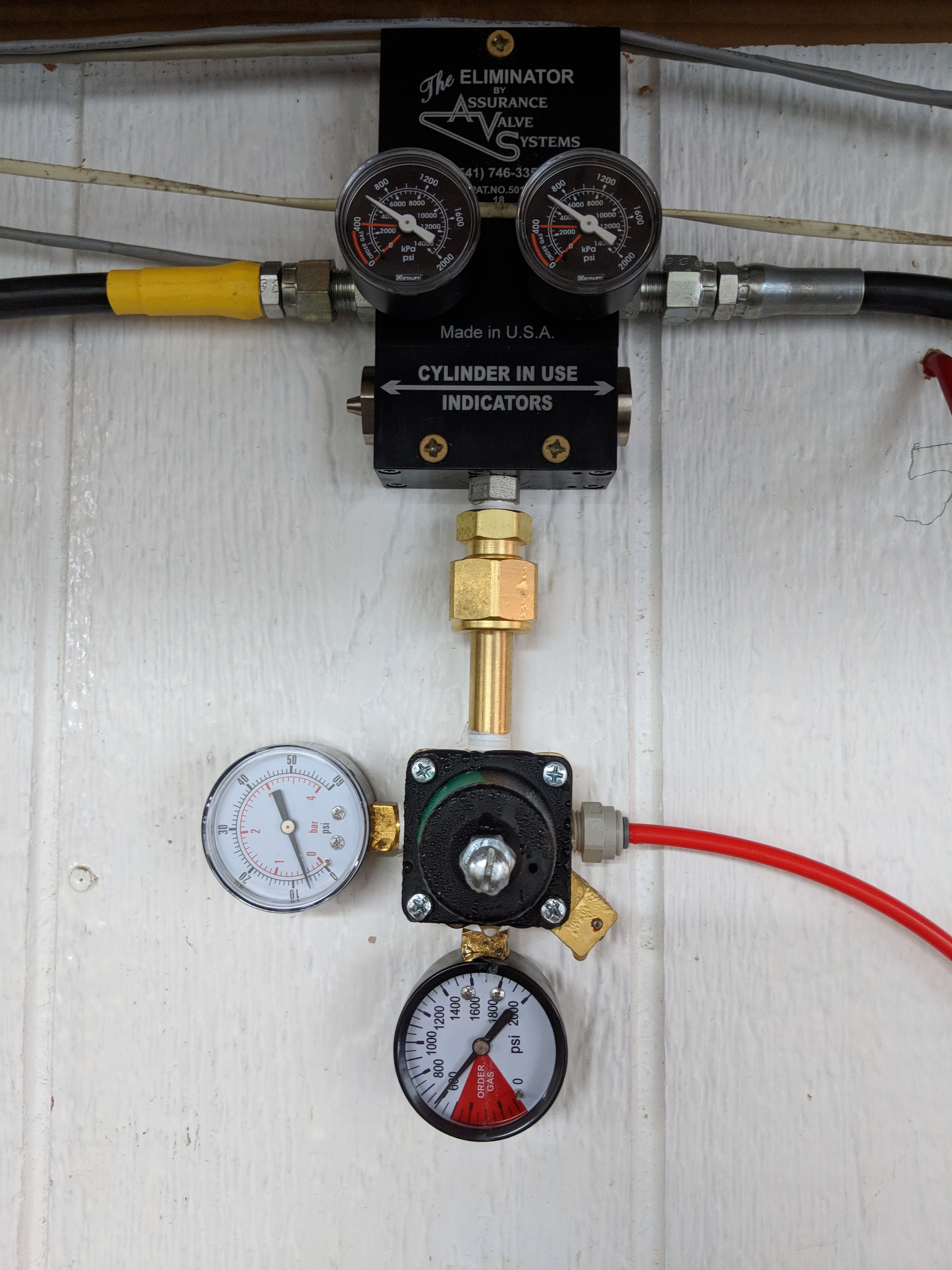

- CO2 gas gauge

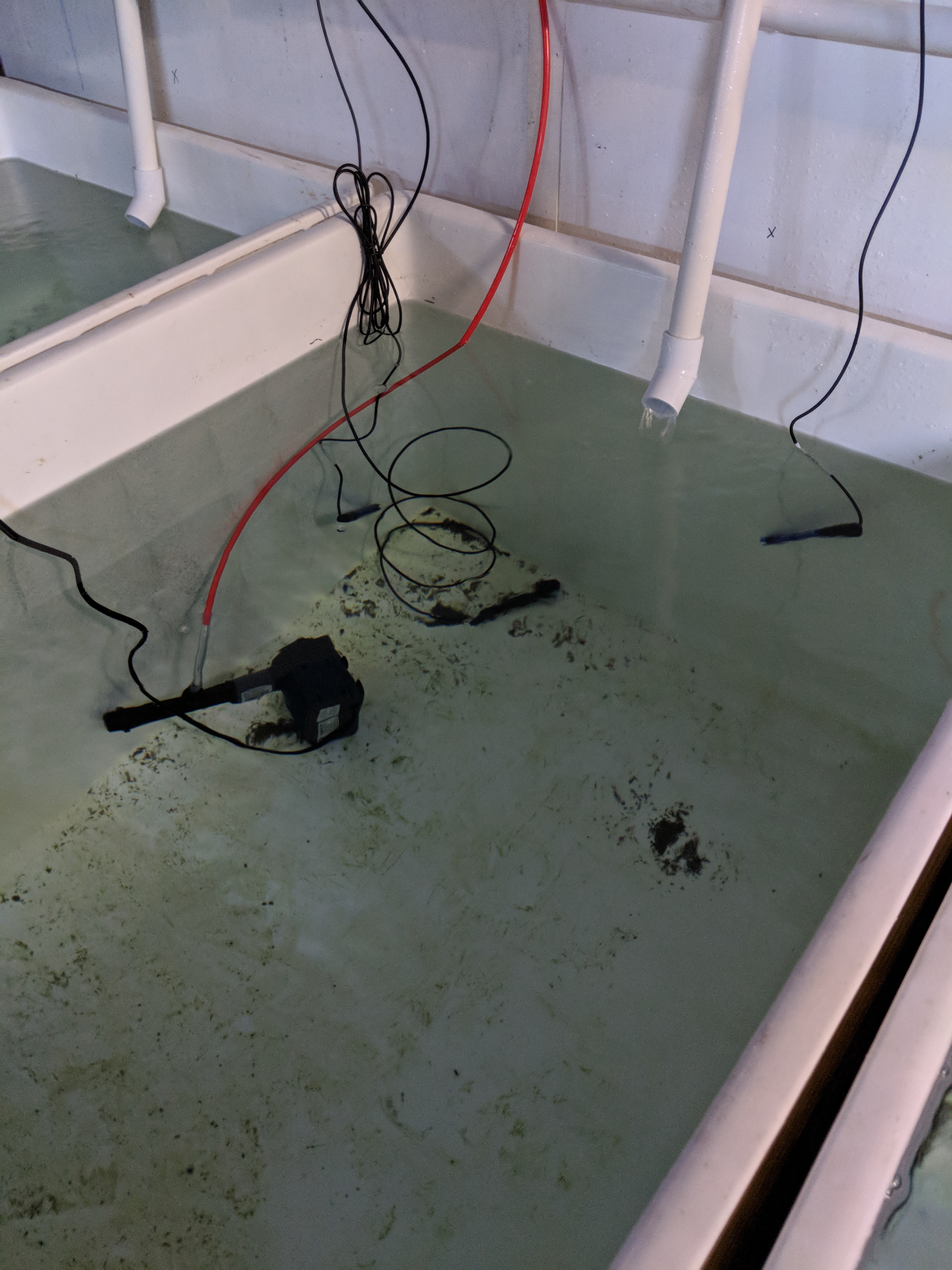

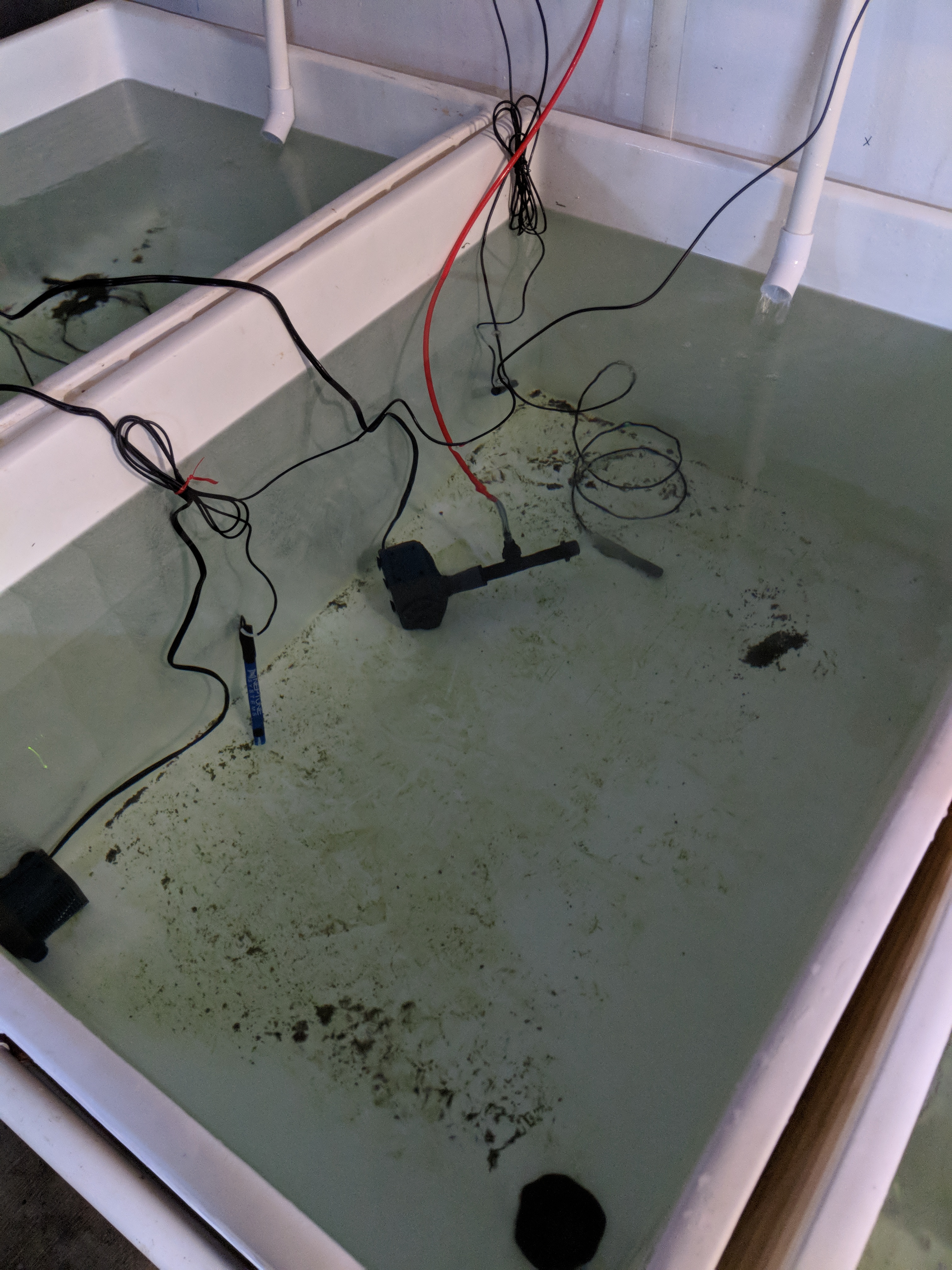

- tank 2 pH probe 3 placement may have been too close to the inflow

- Moved it to the front corner

- Moved it to the front corner

- tank 1 probe placement

- tank 4 probe placement

- tank 1 initial CO2 flow rate

- tank 2 initial CO2 flow rate

Monitoring water chemistry in OA treatments

-

brought waste container and DI water back to Pt. Whitney

-

using the titrator follow this protocol

- will take video next time I run it.

- did about 5 flushes with flicking

- ran pH calibration with pH standards

- ran CRMs

- ran samples

- used measuring cups to sample the water, poured it immediately into glass bottles

- discrete water sample pH, salinity, and temp measurements

-figure out how to download data from Apex Fusion Sam G’s code