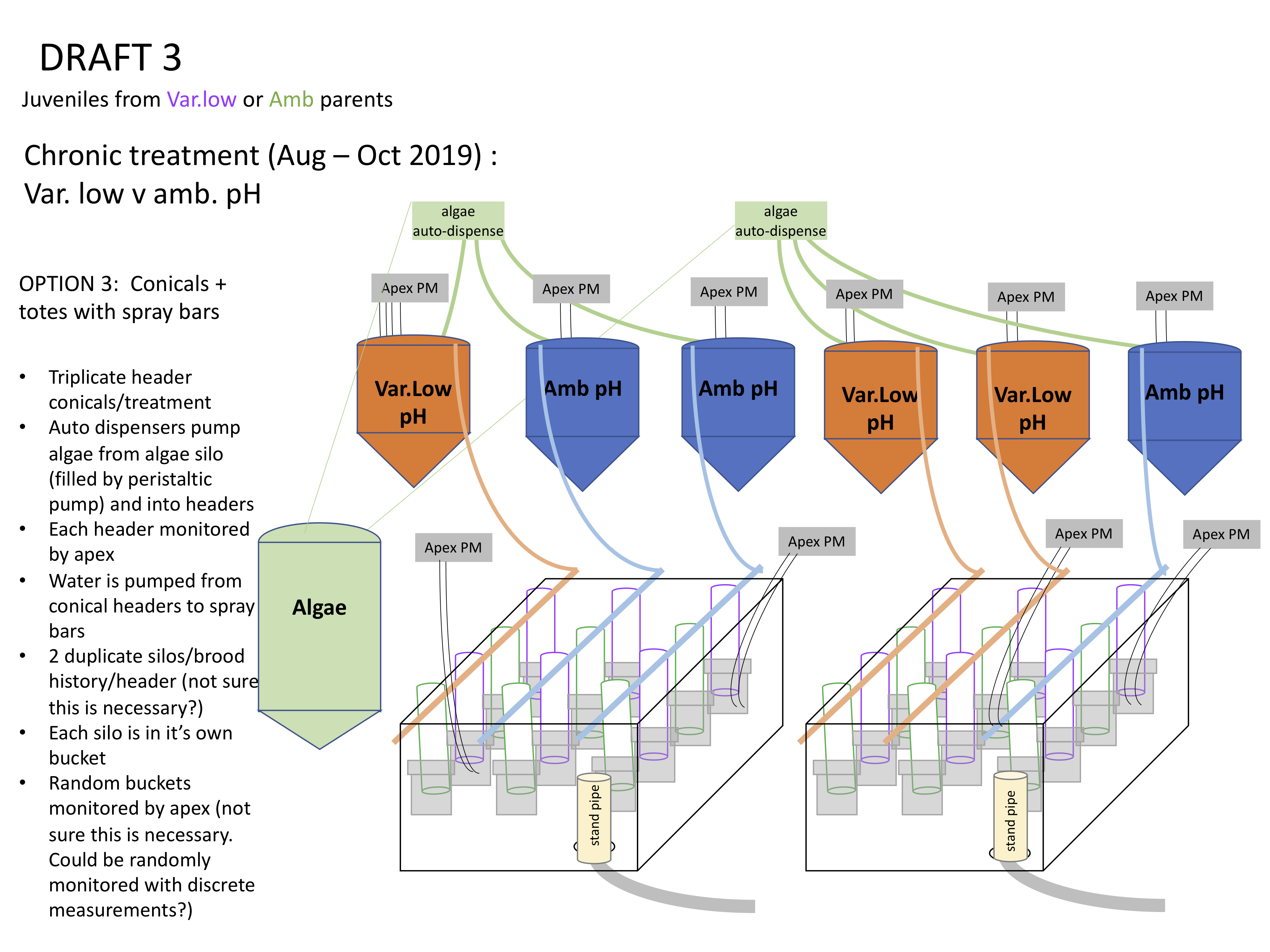

Revised plans to address pseudo-replication concerns:

Equipment brought to Pt. Whitney

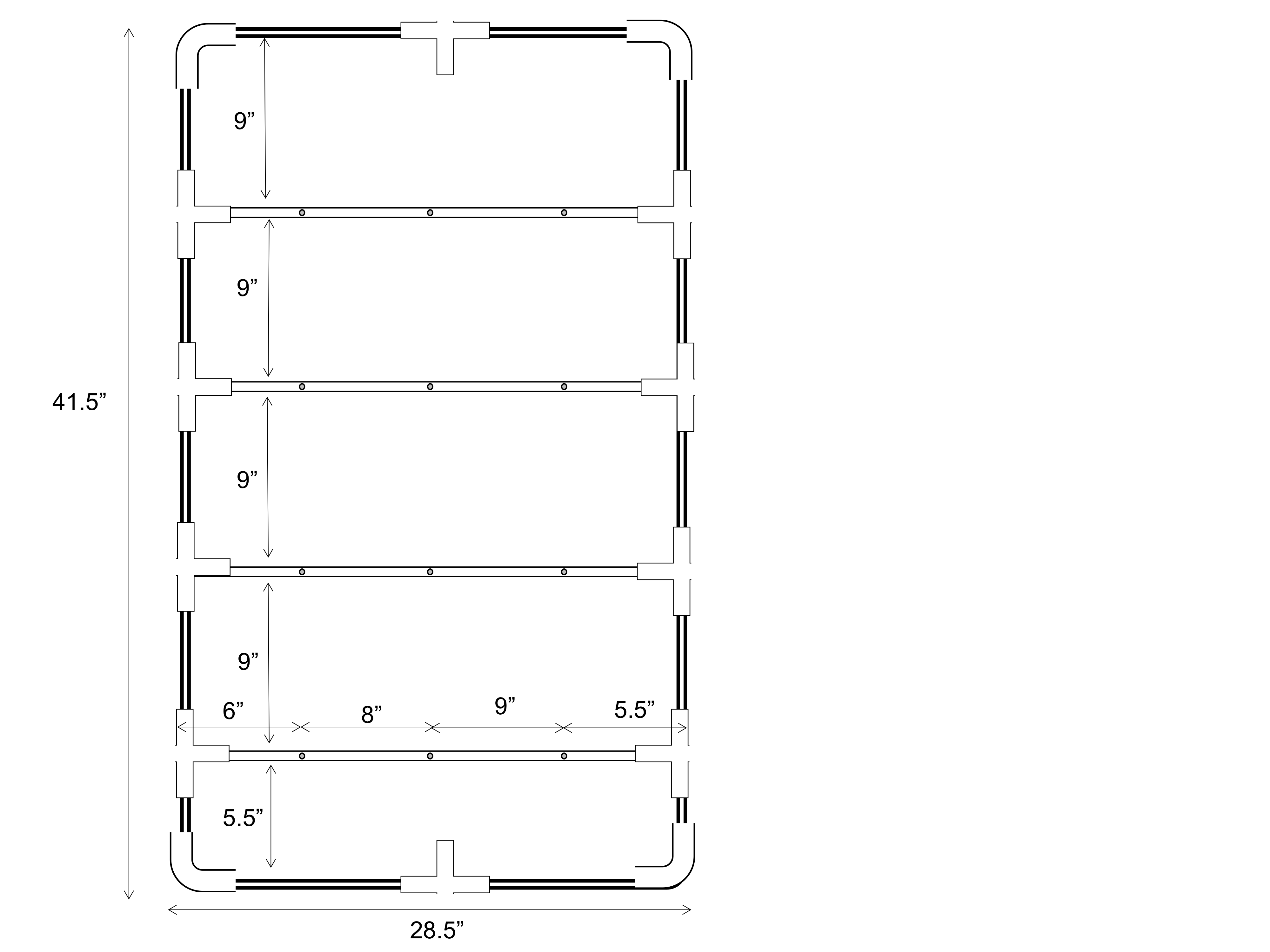

- 6x spray bars (48” x 1/2” PVC with threaded coupler on one end and cap on other)

- 100ft 1/2” tubing

- 8x adjustable aquarium pumps

- 2x 22 piece plastic clamp set

- 4x 7.4” x 13” x 10” 9QT plastic waste basket

- 24x 2.5 QT buckets

Water chemistry

- got apex up and running in big LRT silos

- PH-T2 = var. low treatment

- PH-T3 = ambient

- didn’t actually start the treatment until wed Aug 21

Juveniles

- changed H2 heath stack to upwell

- H1 stack: still fed by gravity

Manila clam setters

- Brent added manila clams

- to some H1 trays

- and to 4 silos on a hang bar + a 1/2” spray bar being fed by another ambient pump (87 gal/hr)

Experimental Set-up progress

- Determined capped spray bars would end up with uneven flow with more flowing out of the holes closest to the in-flow

- roughly eyeballed this with the 2.5qt buckets

- Came up with new set-up based on Mollie’s set up at Taylor

- 3/4” PVC looped manifold with threaded adapters that flow water into silos

- manifold sits over silos suspended by PVC hang bars

- manifold had a port for water to flow in through

Chat with Sam about experimental setup (08/19/2019)

Feeding:

- Sam measured algae density for 2-3 tupperware tanks every week

- took sample in 15 ml falcon tube and used cellometer

- measured 50K cells/ml minimum

- Sam used dosing pumps:

- algae 400-500Kcells (1L/min)

- calibrate 100mL:

- manual pump to fill line and purge b4 calib

- press calib. use grad cylinder to fill 100mL

- settings cycles/day: 24; set time and each hour

- all 4 motors at a time may burn out motor so Sam staggered the dosing

- 15 min for 2 L

- still need to set last channel for brief time, even when not using it

water flow to mesh silos:

- scenario 1: each conical goes to drippers by Ts and 1/4” tubing

- dripper with orange lets out 6 Gal/hr

- pros:

- even flow

- flexibility

- scenario 2: each conical goes to spary bar

- cons:

- uneven flow

- shuffle silos?

- uneven flow

- cons:

overall concerns:

- variable low might differ between conicals

- dosing channel might break

- 2 replicates/ treatment cant really test the effect of conical

- flow rate may change/conical

Next steps:

- monitor water chem in large silos and see if it’s stable

- purchase supplies to build manifold (spray bars, containers, etc.)

- 10x 10ft 3/4” PVC

- 5x 3/4” PVC ball valve (not threaded)

- 5x 3/4” PVC ball valve (threaded)

- 26x 7.4” x 13” x 10” 9QT plastic waste basket

- 25x 3/4” PVC 90 degree elbow

- 40x 3/4” PVC T

- screw tap

- PVC cement

- build manifold and test it

- Sequim bay dig (Aug. 29)

- find new home for deplanted animals

- plan Sequim bay outplant (Aug. 30)